Differences between single and double conditioner

Conditioning provides time for steam and other liquids to be absorbed ensuring uniform distribution of heat. It also improves compressibility and binding properties of feed mixtures by using: heat, moisture and time

From their birth to the present day the conditioners have undergone several changes:

-

Paddles fastened with screws has been inserted to respond to new safety regulations;

-

To facilitate the construction of the machine and a consequent reduction of costs, the steam entry now takes place from the rear side and a bottom drain has been added;

-

To remedy the problem of obturation of the steam outlet holes into the expansion chamber, a tube that enters directly into the conditioner has been inserted;

-

The application of lateral ribs has become necessary to strengthen the carcass, which presented the problem of deformation due to the welding voltages.

Single pellet mill conditioner

La Meccanica single conditioner has a retention time of 8-12 seconds and a plates heating as optional.

It comes complete with: manual shut-off valve, parabolic valve shutter to ensure the constant control of the steam flow, condensate separator and float condensate discharger w

The main advantage of a single conditioner is the lower price.

Anyway, single conditioner can produce decent results, if good processing conditions are achieved and post-pellet cooking is available.

Furthermore, post-conditioning should be considered when double-pass conditioners are not available.

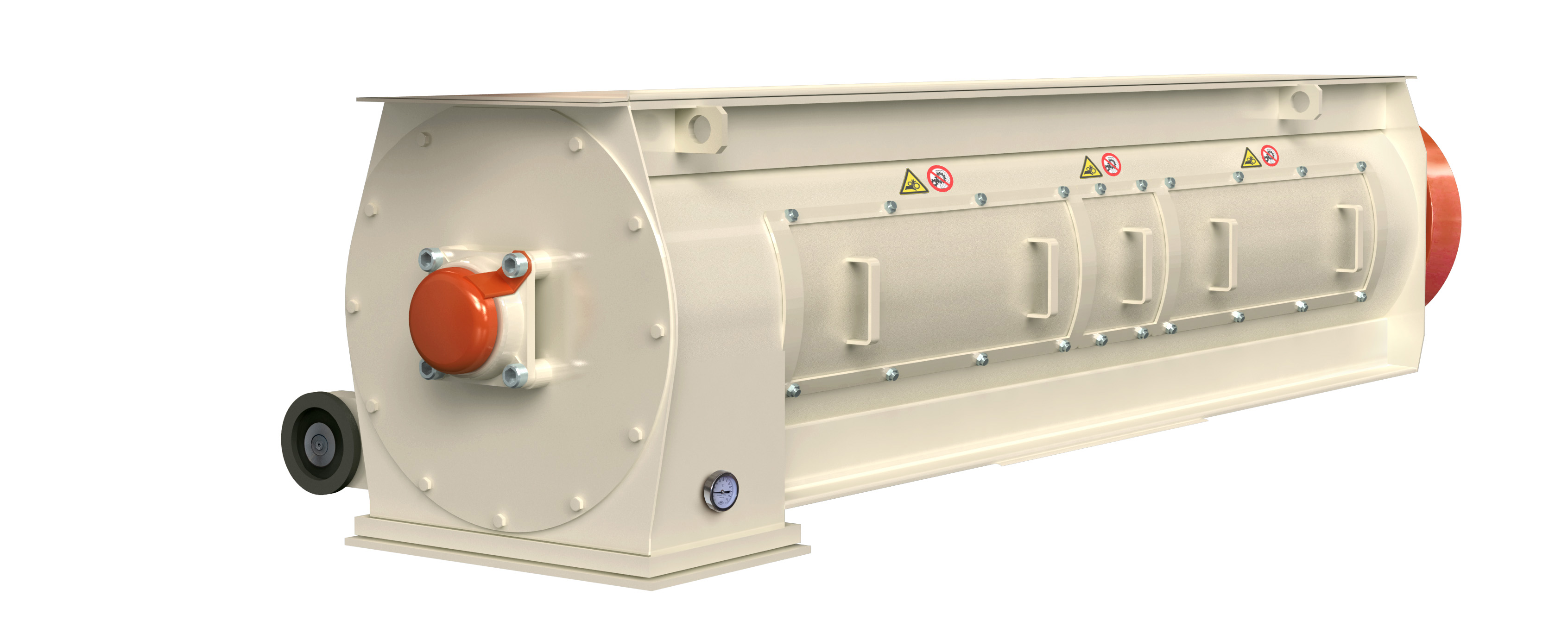

Double pellet mill conditioner (retention time 16-24 seconds)

A better alternative to single conditioner is the double conditioner.

In fact, many poultry and swine operations are turning their attention to double conditioner as a way to increase pellet durability and digestibility and reduce harmful bacteria.

The double conditioner achieve higher mash conditioning temperatures than a single conditioner (97.5 °C vs. 82.4 °C) and the mash moisture increases as well (15.7% vs. 12.9%).

As retention time raise, the steam has more time to condense and transfer its energy to the product. The improvement in mash conditioning also results in better water stability for the double conditioner than that from the single conditioner.

However, higher water stability results are obtained by post-conditioning the hot pellets (92.6 vs. 79.5%).

The double conditioner also guarantees better product’s homogeneity than the single one.