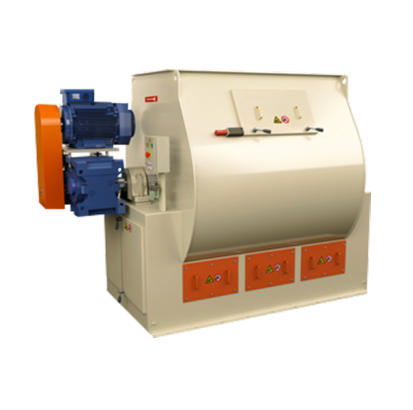

La Meccanica’s paddle mixer series MXP

The paddle mixers ensure faster mixing, but they require more power and the load needs to be central.

Our mixers meet the following specifications:

-

accuracy is guaranteed mixtures homogeneous with a variation coefficient of <5%

-

the homogeneity is achieved after a short a time (2-3 min)

-

the mixed material is carefully treated

-

during discharge, no residues remain in the mixer (hatching accuracy, a risk of cross-contamination)

-

it is possible to add liquids up to 7%

-

filling and discharge times are very short

-

the rate of admission is variable

The paddle mixer can also be partially charged (50% minimum), but in this case, it is not possible to add liquids.

Single shaft mixers

Single shaft mixers are designed for homogeneous mixing of ingredients with good flow characteristics such as meal and other powders. A limited amount of liquid can be added during the mixing process.

The single‐shaft paddle mixer is developed for:

- mixing/stirring dry, solid mealy products;

- mixing liquid in bulk solid products, maximum 8% liquid; - mixing micro‐components into dry, solid products;

- coating pellets/kibbles or crumbs with liquids.

In this case, the speed of the machine must be adjusted to the parameters of the product.

Features:

-

mixing accuracy: 1:100,000

-

coefficient of variation < 5%

-

short mixing time: 120 s

-

Discharge time: approx 15 s

Benefits:

-

Maximum mixing homogeneity

-

No product damage

-

Low maintenance

-

Durability

-

Power rating adapted to an application

-

High uptime

Paddle mixer with double shaft

These horizontal batch mixers are used to mix various powdered ingredients to form a homogeneous mass, to which a limited percentage of animal fats, water and/or vegetable oils can be added without any problems. The main characteristic of horizontal batch mixers is excellent, rapid mixing. Even materials with very different densities and/or a fragile structure can be mixed in a few minutes to form a homogeneous mixture. The mixer has a shaft with four or more paddles. The opposing direction of transport of the inner and outer paddles provides the mixing effect.

Thanks to the special profile of the blades, after mixing in suspension and falling at the bottom of the machine the product circulates around the bottom of the machine and then is picked up again by the blades themselves. This particular is important as the product is never demixed.

The rotation of the blades of the two rotors is divergent. The product is collected from each rotor and lifted to the upper middle part where the mixing takes place. Due to its principle of working, the paddle mixer with double shafts must work by half load.

The rotation speed is slower compared to that of a single shaft. This can be advantageous when mixing brittle ingredients for pellet covering operations.

The mixing time is significantly lower compared to that of a conventional one.

New comment