The pelleting process

Pelleting is an extrusion thermoplastic moulding operation. In fact, during this process, the proteins and sugars of feed ingredients become plastic when heated and diluted with moisture. Pelleting is a key to the production of high-quality nutritional feeds as they ensure that the feed formulation is in the correct quantities to meet the nutritional needs of each animal. Each bite of a pellet will have the same designed formulation ensuring all the stock are feed as intended.

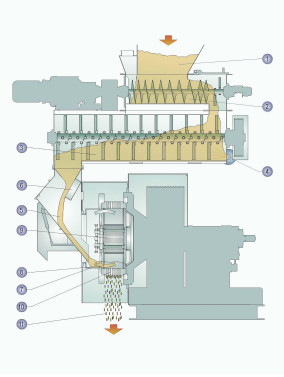

The pelleting system is composed of several different machines designed to most efficiently accomplish the pelleting task. The pelleting process starts with a bin in which the mixture of the mash is stored.

From there, the mash passes through the screw feeder, the conditioner and arrive into the pellet mill. This machine is usually located on the ground or main work floor level. The hot (about 85-90°C), extruded mash (pellets) flows by gravity into a cooler where it is held for three to six minutes while being cooled and dried by a flow of air. The air is drawn through the mass of pellets and passed into a dust collecting device, such as a cyclone collector. The dust from the outlet of the collector is returned to the bin on the top of the pellet mill to again be compacted into a pellet.

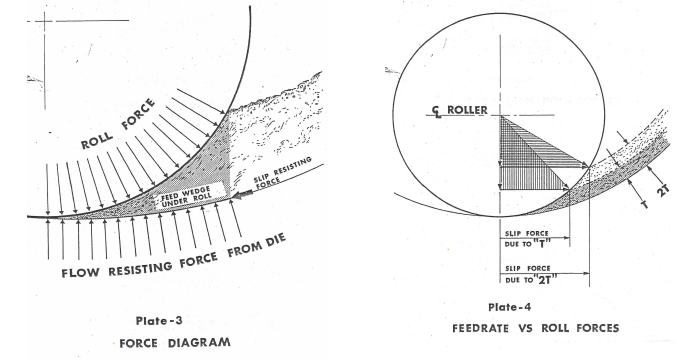

The process of pelleting consists of forcing a soft feed through holes in a metal dies plate to form compacted pellets which are then cut to a predetermined size. When sufficiently controlled compression is applied to the “conditioned” feed ingredients, they will form a dense mass, shaped to conform to the die against which they are pressed. When the heat and moisture are again withdrawn (dried and cooled) as to withstand moderately rough handling without excessive breakage they have retained or enhanced their nutritive value.

In modern feed mills, the ingredients are usually stored in bins above a weighing system composed of one or more scales. Those ingredients, which are of coarse texture, such as whole grains and other fibrous materials, are ground into a fine meal to facilitate the pelleting and mixing process. Weighted quantities of each ingredient are thoroughly mixed in a batch mixer and then conveyed to a bin above the pellet mill. Attention, before being mixed the products must be ground.