Why are plastic pellets produced?

Plastic recycling is the process of recovering scrap or waste plastic and reprocessing the material into useful products. Recycled plastic pellets and regrind are one of the easiest, most cost-efficient ways to reduce your carbon footprint, while at the same time-saving money.

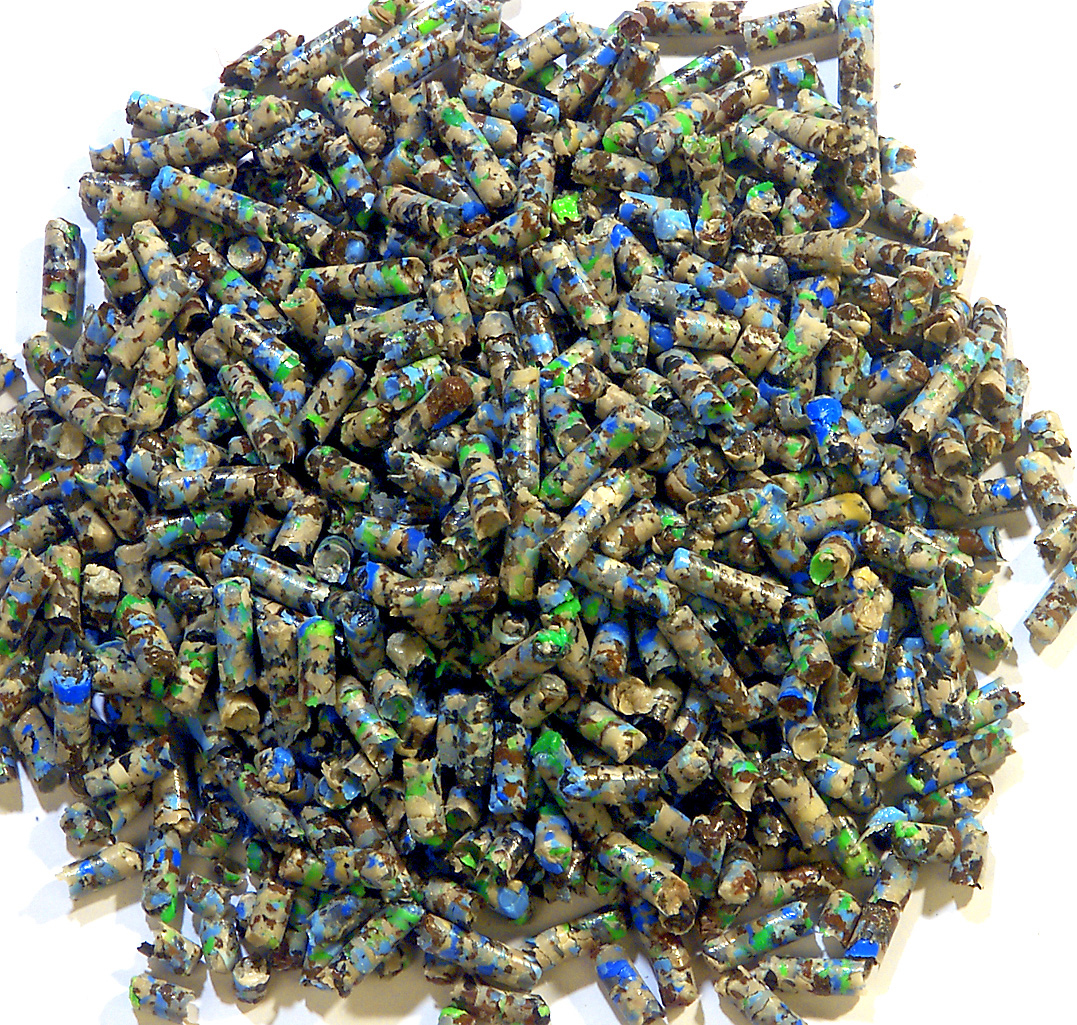

They are essentially the middle line between waste plastic and the manufacturing of finished goods. Creating recycled plastic pellets is usually the final step in the recycling process before the material is distributed for the industrial production stage.

Once the waste plastic has been put through a plastic grinder and broken down, the smaller pieces are melted and compressed into recycled plastic pellets. These final recycled plastic pellets are a high grade of enhanced, recycled material that is ready for remanufacturing. Further processing may include separation based on density and even computer colour separation.

Plastic for packaging

Seven groups of plastic polymers, each with specific properties, are used worldwide for packaging applications. Each group has its plastic identification code (PIC), introduced to provide a uniform system for the identification of various polymer types and to help recycling companies separate various plastics for reprocessing.

| Type | Features | Uses |

|---|---|---|

| PET, PETE | Clarity, strength, toughness, barrier to gas and moisture. | Soft drink, water and salad dressing bottles, peanut butter and jam jars, small consumer electronics. |

| HDPE | Stiffness, strength, toughness, resistance to moisture, permeability to gas | Water pipes, milk, juice and water bottles, grocery bags, some shampoo/toiletry bottles. |

| PVC | Versatility, ease of blending, strength, toughness | Blister packaging for non-food items cling films for non-food use, electrical cable insulation, rigid piping, vinyl records |

| LDPE | Ease of processing, strength, toughness, flexibility, ease of sealing, a barrier to moisture. | Frozen food bags, squeezable bottles, cling films, flexible container lids. |

| PP | Strength, toughness, resistance to heat, chemicals, grease and oil, versatile, a barrier to moisture. | Kitchenware, yoghurt containers, microwavable disposable takeaway containers, disposable cups, soft drink bottle caps, plates. |

| PS | Versatility, clarity, easily formed | Egg cartons, packing peanuts, disposable cups, plates, trays and cutlery, disposable takeaway containers. |

| Other | Dependent on polymers or combination of polymers | Beverage bottles, baby milk bottles, compact discs, unbreakable glazing, electronic apparatus housing, lenses, prescription glasses, automotive headlamps, riot shields, instrument panels |