All news

Press review Repuestos

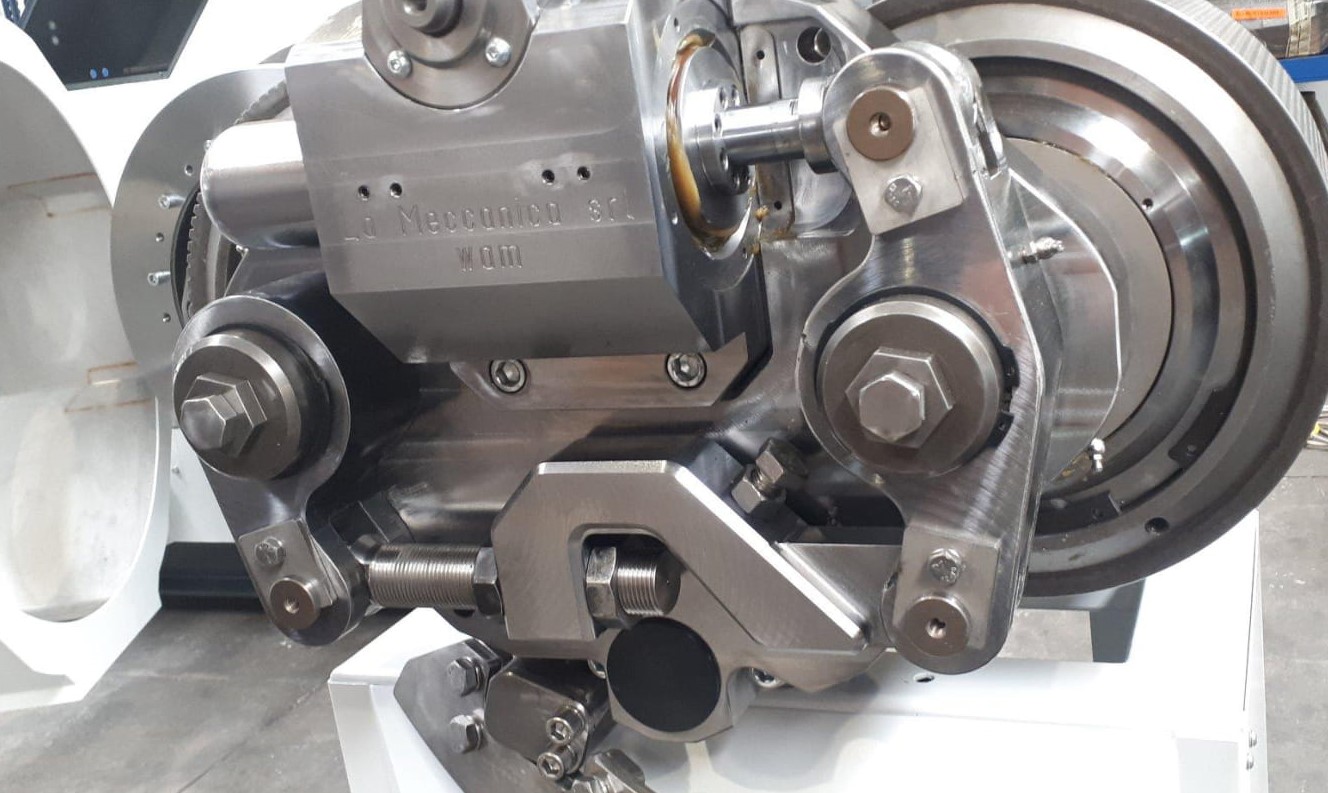

Mechanical Rolls Adjustment (WAM)

The WAM system makes possible to set the distance between the rolls and the die from remote, while the machine is running.

The WAM system makes possible to set the distance between the rolls and the die from remote, while the machine is running. The integration of the WAM roller adjustment with the rolls anti-slippage device (sold separately as optional) allows to maximize the output of the pellet mill and the pellet quality

Reason for choosing a Wam System

WAM’s characteristics

- The engineering of the transmission of motion to the rollers allows to maximize their diameter.

- The WAM system was designed in such a way that, while working, the strains (even pulsive), act on static components thus sparing dynamic parts such as the roller bearings. The system is sealed in order to avoid contamination of the mash by the lubricants.

- Stainless steel frame.

- Rolls set up by PLC, touch screen control panel.

- The setup of each roll during setup is independent, instead while working the two rolls work simultaneously.