Roller adjustment

The adjustment of the distance between roll and die affect remarkably the pelleting process.

The spacing between these rolls and the inner surface of the die is critical and must be adjusted to the correct measurement “gap” to force the mixture from the roll through the die without the mix slipping and not entering the die correctly.

This is called rollers slippage and it causes the blockage of the machine.

If enough mash material enters the rolls area but isn’t forced into the working track, the pellet mill will plug and has to be stopped and cleaned out before continuing production.

If many formulas are pelleted, it may be critical to adjust the feeder roll gap to force the mixture into the die holes for different ingredients.

By using the right roll gap, the die and roll lifetime can be increased.

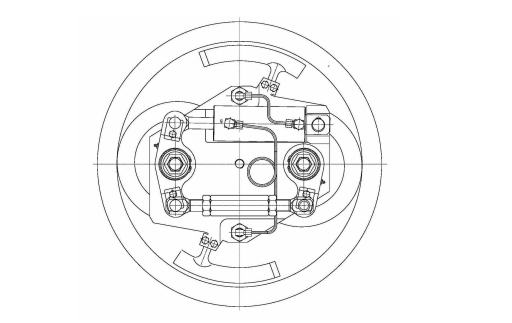

There are two types of rolls adjustment: mechanical also called WAM and hydraulic adjustment with the ON - OFF System and the WAP System.