Remote control of the position of the rolls

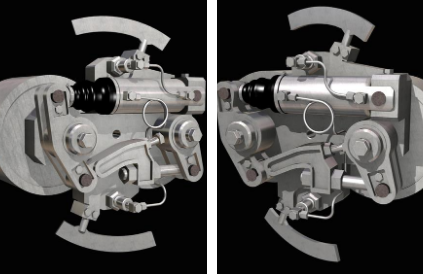

The ON-OFF system allows to adjust the position of the rolls, switching from the rest position (OFF) to the working position (ON), or to quickly remove them in order to clean the die after a blockage or during a work stop. The system is simple, powerful and rapid.

Thanks to this device, an operation that normally takes many minutes, can be performed in 20 seconds. The rolls are regulated with a hydraulic piston operated by a hydraulic control unit. The hydraulic piston is moved by the hydraulic pump, external to the machine, which sends the oil through the main shaft passing through the two tie rods of the front plate.

With the "ON-OFF" system it is possible to adjust the rolls in two positions:

1. Near the die at a fixed point defined with the mechanical lock.

2. Away from the die at a fixed point defined by the manufacturer. The hydraulic power unit pressurizes the hydraulic circuit and moves the piston until the rolls reach the desired position, defined by the mechanical lock. When the piston has positioned the roll at the limit switch, the pressure control unit sends a signal to the hydraulic pump which will keep the rolls permanently in position. The hydraulic circuit calibration pressure is 220 ÷ 300 bar. The minimum pressure needed to move the piston and therefore to adjust the rollers is about 150 bar.

Reasons for choosing the ON-OFF system

- Precise and quick position of the rolls

- Independent rolls registration by the operator

- Quick to restart the press after a blockage

- No need for potentiometer

- More power in recording the roll then with the mechanical adjustment

Is the system failing? What are the problems encountered over time?

Like all mechanical systems, the ON-OFF can also have anomalies. In particular, there may be oil leaks. But the hydraulic circuit is equipped with a pressure switch. The system goes into alarm if the pressure falls below an alert threshold or if the pump cannot restore the working pressure. In these cases it is however possible to work with the pellet mill by replacing the hydraulic piston with an emergency tie rod supplied.