Focus on hammer mills

Hammer mills are indeed commonly used in the production of animal feed.

These machines are designed to grind or crush different materials into smaller particles or powders, making them easier for animals to digest. In the context of animal feed production, hammer mills are used to process various grains, such as corn, wheat, barley, and soybeans, as well as other ingredients like dried grasses, straws, and even certain industrial by-products.

La Meccanica first hammer mills

During our over 60 years of history in animal feed machinery production, our hammer mill has undergone numerous transformations, improving every time in technical characteristics and design till it has become today's infallible machine.

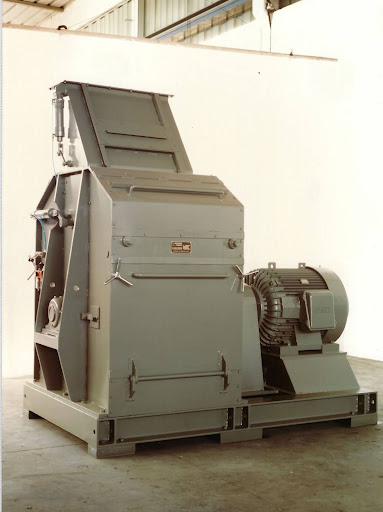

One of our first hammer mills

was build for organic fertilizer in 1979.

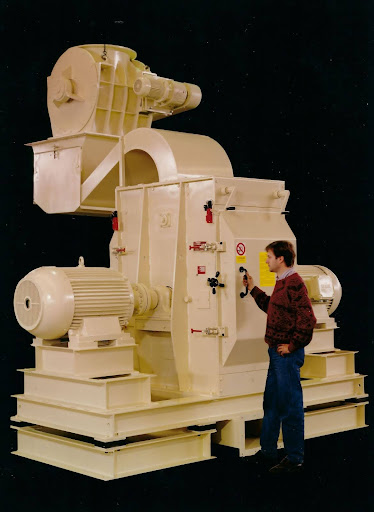

After the 80s La Meccanica started building hammer mills for cereal crushing, from 1985 to 1990 our hammer mill had different changes from the dimension of the rotor to the product chamber and dispositions of the doors.

In 1994 was the turn of the hammer mill for alfa alfa production. In 2003 the machine changed once again with the addition of the roller feeder and the air separator.

The main components of a hammer mill typically include a rotor with hammers or beaters attached, a chamber where the material is fed into, and a screen or grate that controls the size of the final product. When the rotor spins at high speed, the hammers impact the material, breaking it into smaller pieces.

Overall, hammer mills play a crucial role in efficiently processing animal feed, helping to ensure that animals receive the necessary nutrients in a form that is easily digestible.

The versatility of hammer mills makes them suitable for various applications in animal feed production. They can be adjusted to produce different particle sizes, depending on the specific requirements of the animals being fed.

La Meccanica new hammer mills

EASY, VERSATILE AND RELIABLE

La Meccanica’s hammer mills models MM are characterized by:

- function-oriented design

- heavy duty construction

- two or four pole motor

- motor power from 15kW up to 550 kW

- direct coupling of the rotor through an elastic coupling

- bidirectional rotation

- rotor with dynamic balance

- screen that can be manually withdrawn from the side of the mill

- bearing temperature control

- temperature sensor PT 100

- access door to the grinding chamber equipped with a safety block system

- quick sieve change

- fast and easy hammer change

- easy replacement of grids

- automatic mill dosing

- pneumatically and manually reversible inlet flap

- low noise and long live through low wear bearings

Discover more about La Meccanica Hammer Mills MM by downloading the catalog