LEARN MORE ABOUT US

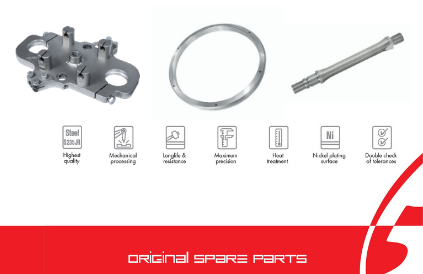

Production of machinery, plants and spare parts for the animal feed, biomass, recycling and fertilizing industries entirely Made in Italy.

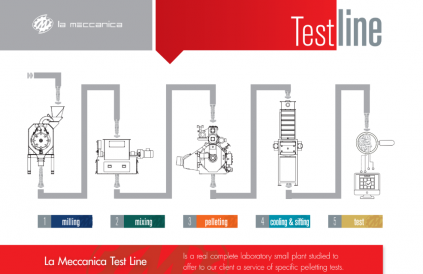

Advanced machines and targeted solutions for sifting, crumbling, milling, mixing, cooling and pelleting processes.

Events&Fairs

In Evidence

La Meccanica engages to make a better tomorrow with sustainable industry, intervening in improving the production processes with advanced technology, reducing energy consumption, avoiding waste and the use of polluting products and making environmentally sustainable activities.

Discover our social commitment and contribution to preserve and emerge the Art and the Culture of our territory.

Our involvement in non-profit activities impact on employees, communities and society.

The academy is born within La Meccanica organization to share knowledge, information and values.The LM Space academy aims to train the employees of each department and open for the training of Italian and foreign clients.

SOME NUMBERS OF LA MECCANICA

MACHINES

DESIGNED AND MANUFACTURED

DIES PRODUCED

PER YEAR

DRILLED DIE HOLES

IN KILOMETERS

ROLLER SHELLS

PRODUCED PER YEAR

CHIPS

IN TONS

Mixing process

Why are mixers so important?

The mixer plays a vital role in the feed production process, with efficient mixing being the key to good feed production. In fact, only the perfect mixing of the feed ingredients will ensure uniform distribution of nutrients, vitamins and minerals, which will result in a homogeneous nutrient content in each feed pellet. Further, it will ensure optimum growth of the animals.

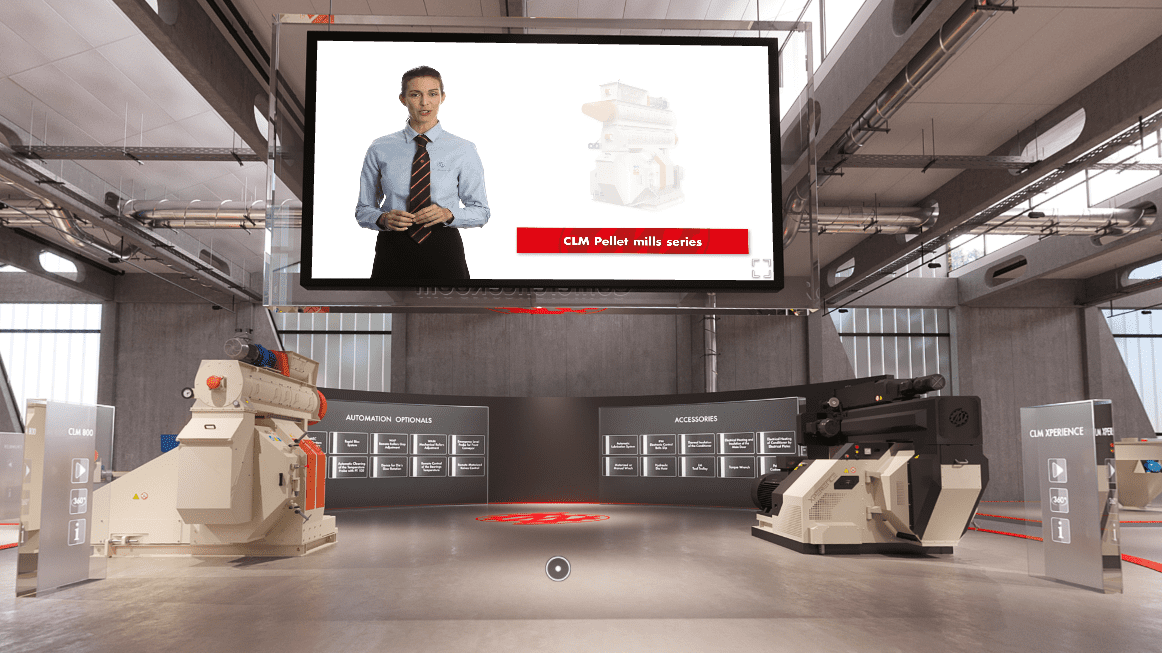

Do you want to know better La meccanica, the products and its history? Visit our company, the conference room, the showroom and the pellet test line! Ask for a guided tour in our virtual platform

or start a virtual visit on your own

_0.png)