Press Review Animal Feed

Client area

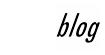

Hammer mills are indeed commonly used in the production of animal feed.

READ MORE

Press Review Animal Feed

Reasons for pellet cooling

In the pelleting process, cooling is essential for several reasons, cooling is required to prevent mold and stabilize the residual moisture.

READ MORE

Press Review Animal Feed

Reasons for conditioning

Conditioning, or adding heat and moisture in the feed mill during the pelleting process, is a way to optimize pellet quality, but proper methods must be used to achieve the best results.

When dealing only with the pelleting system, it is apparent that conditioning is the most important factor that influences pellet quality.

READ MORE

Press Review Animal Feed

Reasons for pelleting

Pelletizing is the key to the production of high quality nutritional feed, as the substances that make up the formula are in the correct quantities to meet the nutritional needs of each animal.

READ MORE

Press Review Animal Feed

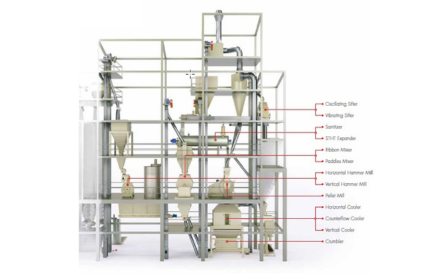

Energy consumption in a pellet plant: how to reduce it?

On average, electricity and thermal energy represent about 6% of the production cost of feed. Given the latest increases in electricity prices, this percentage has a huge impact on the cost of the final product.

READ MORE

Press Review Animal Feed

When does the pellet mill become clogged?

Your pellet mill has blocked producing pellets? This can affect not only the production of pellets, but also the machine and spare parts. Let's find out when the pellet mill becomes clogged and how to overcome this problem.

READ MORE

Press Review Animal Feed

Pellet Mill Customization VI

All our pellet mill models can be customized following the need of the client.

Our objective is to supply all our customers with the machine that best meets their needs.

READ MORE

Press Review Animal Feed

Pellet Mill Customization V

These devices are useful to improve your production process and avoid damages to pellet machines.

READ MORE

Press Review Animal Feed

Pellet Mill Customization IV

These personalizations are useful for facilitate movement and monitoring the pelleting process.

READ MORE

Press Review Animal Feed

Pellet Mill Customization III

In this section you can find the components build for a fast installation and removal of the die. They are very important because permits easy maintenance operation and prevents damage.

READ MORE

Press Review Animal Feed

Pellet Mill Customization II

La Mecccanica Pellet Mills have a variety of components for customization that are highly recommended for achieving the best performance and feed pellet quality.

READ MORE

Press Review Animal Feed

Pellet Mill Customization

La Mecccanica Pellet Mills have a variety of components for customization that are highly recommended for achieving the best performance and feed pellet quality.

READ MORE