Client area

All news

Press Review Animal Feed

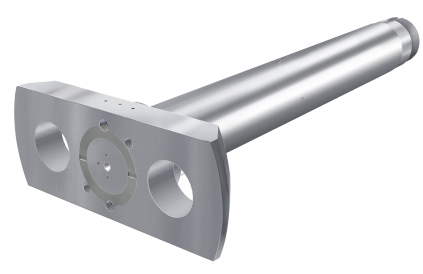

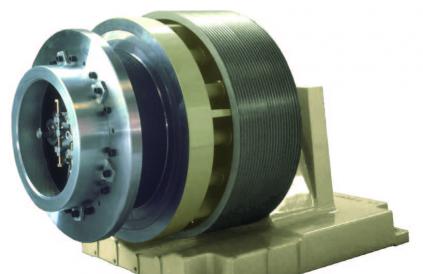

In this section you can find the components build for a fast installation and removal of the die. They are very important because permits easy maintenance operation and prevents damage.