All news

Press review Biomass

Wood or biomass pellet production plant

La Meccanica manufactures and supplies processing machine in the wood or biomass pellet production line. The mission of our equipments and complete line dedicated to the

biomasses is to help solving the problems of the environment realizing an efficient pelletizing process.

La Meccanica manufactures and supplies processing machine in the wood or biomass pellet production line. The mission of our equipments and complete line dedicated to the biomasses is to help solving the problems of the environment realizing an efficient pelletizing process.

Let's take a look at the process flow for wood and biomass pelleting.

A wood pelleting plant production is composed of the following sections:

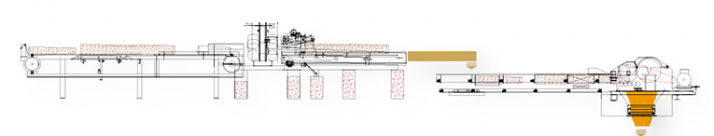

- Debarker line

Is where the wet raw material (wood logs) stored into warehouses, is loaded into the cross chain feeder

- Chipper line

The wet raw material (wood logs) stored into the second cross chain feeder, it is loaded into the chipper machine by a belt conveyor complete with a metal detector. Chipping process reduces the granulometry of raw material in order to have available size for wet milling process.

- Wet Hammer Mill line

The wet raw material (wood chips) stored into warehouses or it is loaded into the hammer mill by loading hopper.

Wet milling process reduces the granulometry of raw material in order to have available size for the drying process.

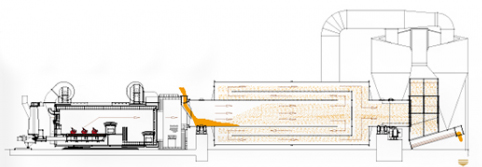

- Drying line

The wet raw material (sawdust and / or wood chips) stored into warehouses or coming from wet hammer mill, is loaded into the dryer loading hopper. The drying process evaporates the water contained in the wet raw material up to the moisture content suitable for the pelletizing process. It consists in investing and continuously crossing the material with hot air for a certain period of time. The air is heated by a solid fuel combustor (biomass) or by using the thermal energy supplied by the adjacent cogeneration plant or biomass boiler, by hot water and combustion fumes.

- Screen line for dry wood chips

The dried wood chips discharged from the dryer, is conveyed to the sifter equipped by the screen with small square holes in order to separate small particles from chips cleaning it from bark, sand and silica residuals. It allows reducing wearing action of pellet mill spare parts and to reduce dark pellet color.

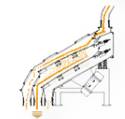

- Pelleting line

The dried material discharged from the dryer, is conveyed to the hammer mill to standardize and adapt the size of the raw material to the extrusion process. The pellet mill loaded by the storage silo for dried material duly grounded, produces the wood pellets by a suitable die with holes of 6 mm diameter (at the user's choice), thanks to the layered compaction of the sawdust into the holes of the die.

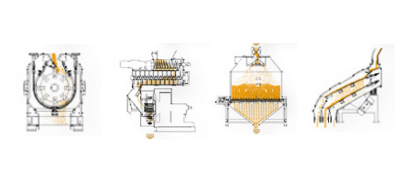

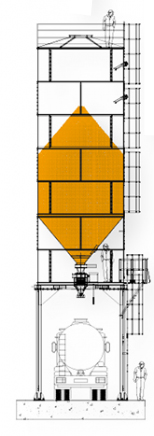

- Storage system for pellet in bulk

The storage system consists of one or more silos receiving wood pellet from pelleting line by conveyors. The system is equipped with a sifter in order to clean wood pellet from dust before discharging it into truck tanks. Alternatively wood pellet can be returned to the packaging system for packing into bags or big-bags.

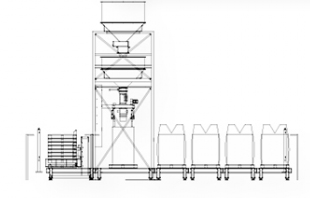

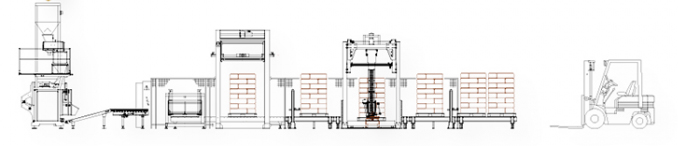

- Packaging system (bagging and palletizing)

The packaging consists in bagging the wood pellets produced into 15 kg bags for domestic use or in 1,000 kg big-bags each for industrial use, by means of suitable bagging scales. To finish the 15 kg bags for domestic use they are packaged on pallets duly wrapped in plastic film to avoid damage during transport and storage.

Keep reading our articles to see the specification of the main section and the working principles of the wood pelleting plant.