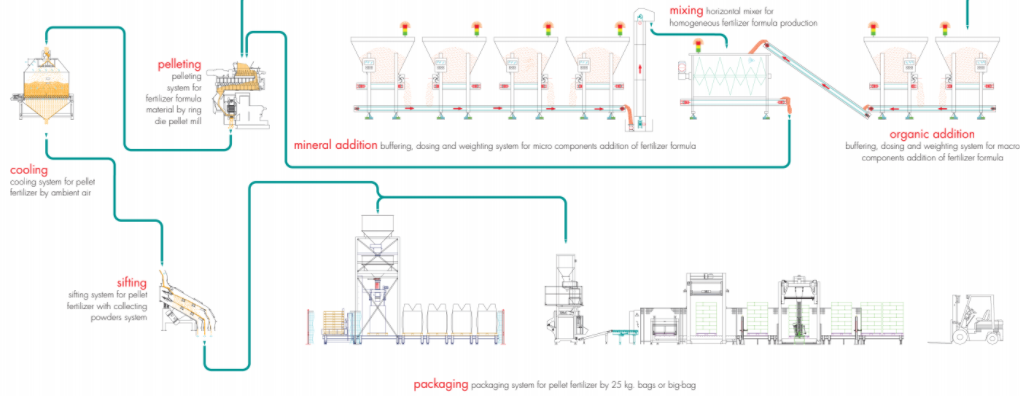

Fertilizer production process

1. Mineral - Organic Addition

Minerals can be bulk or in bags (big or small).If bulk, they go through some hoppers, loaded with a loader, and then through a dosing system and a conveyor; if they are in a bag, the bag is mounted on a rack with a hopper under it, and then, as per the bulk, the material go through a screw extractor, a dosing system and a conveyor to the mixer.

About the mineral addition, there are 2 important issues to consider:

- Since the minerals have a moisture content = 0%, the quantity of mineral added to the organic material, will affect the humidity proportionally

Example: Moisture content of the compost 30%, if 20% of minerals is added, the total moisture content of the compost will drop to 24%. - The higher is the percent of minerals added, the lower will be the production of the Pellet Mill

Example: a Pellet Mill Mo. CLM520, with 100% organic compost, reach a capacity of 5TPH; if 40% of minerals is added, the capacity drop to 2.5 TPH

2. Mixing

About the mixing, the most commonly used, is the ribbon mixer; there’s also the possibility to mix in continuous instead of in batches, with a mixer similar to a conditioner, but batch production in preferable.

3. Pelleting

The pelleting process of the fertilizers is particularly heavy for the Pellet Mill and, for this motivation, La Meccanica has designed a heavy-duty machine for this purpose.

The material should arrive with a maximum moisture content up to 20% but, as aforesaid, in the case of the drying of the pellets after the pelletizing, the compost can arrive at the Pellet Mill with a moisture content of 30%. Find out more about the Fertilizer Pelleting Process in the dedicated article.

4. Cooling

The cooling operation is usually performed by a Counterflow Cooler but horizontal or vertical coolers can be used as well.

The cooling operation is important and has to be done well because the pellet must arrive at the bagging with a humidity lower than 15%, in order to avoid fermentation inside the bags. If the fertilizer will be used within one week from the production, a 20% of moisture content is acceptable but usually, in this case, the pellet is not bagged.

5. Sifting

Sifting operation is performed by a normal horizontal sifter with one, two or three screens.

6. Bagging

Usually the fertilizers pellets are bagged into bags of 25Kg but, off course, there are many other options like bulk loading of tracks, big bags and so on ... it depends on from the customer specification.