Production phases of La Meccanica Dies II

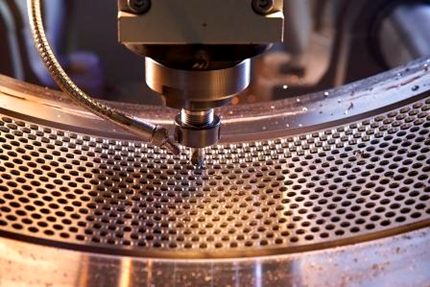

6. Countersinking process

It is a process that is carried out in the internal part of the die and consists in creating a conical invitation to the holes of 60° to facilitate the entry of the material that would

otherwise be prevented by the edge of the hole itself. Countersinking is a very important process: in fact, an irregular flaring causes irregular operation of the die: clogging and /or vibrations are often due to too deep flaring or flaring at a not constant depth. The irregularity of the countersink is due to the very subjectivity of the workmanship. In practice, the depth of the countersink is defined on the basis of the operator's experience and therefore varies from operator to operator.

The surface finish of the flare is also significant: the cone of the flare can exhibit longitudinal or circumferential vibrations. The cause of this are the characteristics of the steel: a steel that is too soft forces the countersink tool to tear the chip, with the result of an irregular surface.

The surface of the countersink would be much better if it were reworked after the heat treatment, but this is not easy as the tools are quickly damaged when used on the hardened material and therefore the countersinking operation would be very expensive.

Countersinking times: On average, 8 to 10 dies are flared per day.

7.Die Hardening - The hardening cycle takes 9 hours.

The piece is loaded into the furnace and tempered at a temperature of 1040 °C. The result is an extremely hard but brittle product.Then a subsequent tempering operation is carried out at 190-200 C° which serves to remove the internal tensions due to hardening making the product more resistant (more resilient). At the end of the treatment, the hardness index is around 53/54 HRc

8.Control (Hole diameter, countersinking quality)

Time control and continuous quality control in finishes make the product extremely competitive. The die's surface hardening is tested before delivery to ensure premium quality.

9. Finish - The finish concerns the shoulder of the die and is carried out before the piece is ground.