Wap roll regulation system

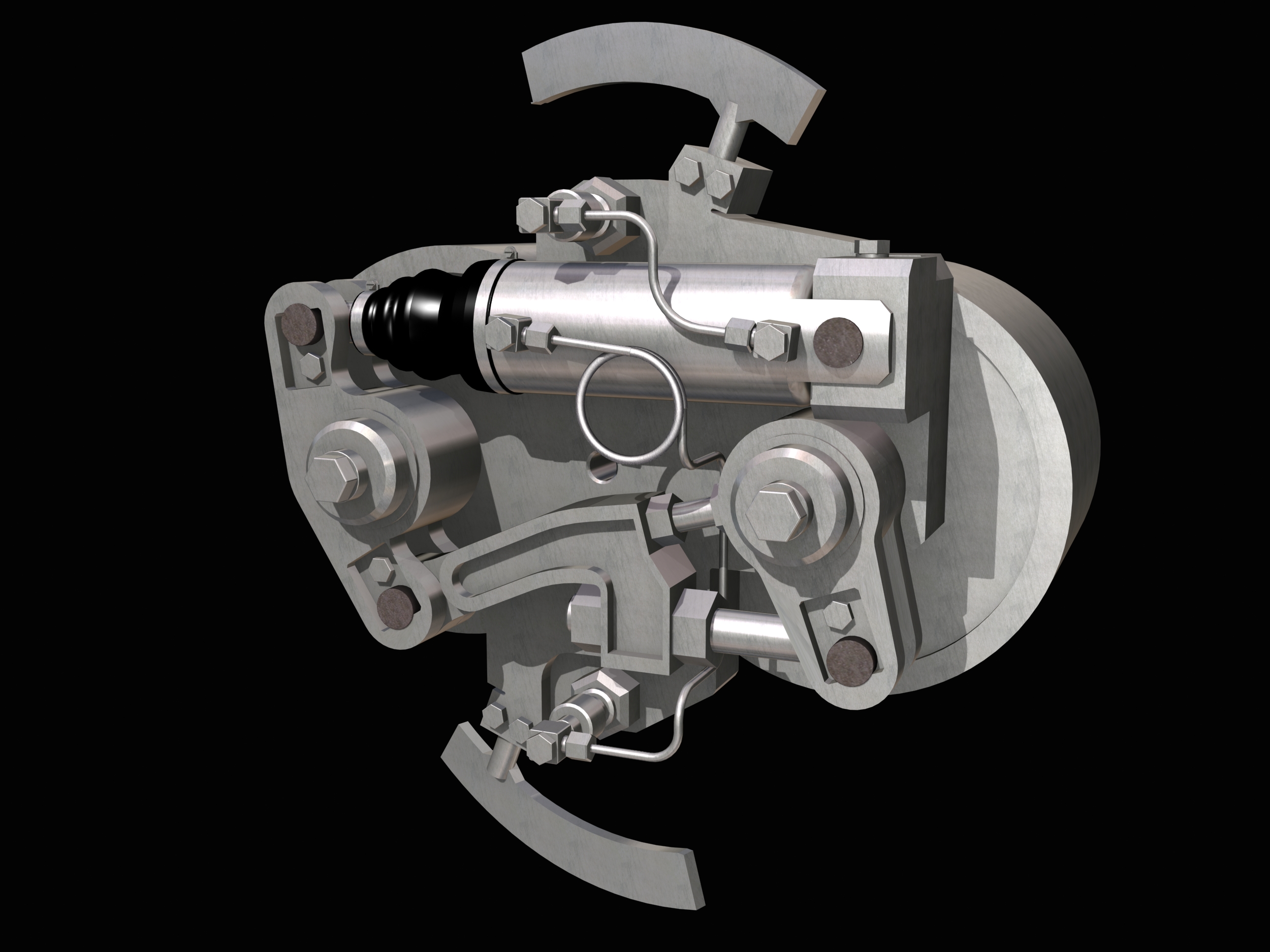

The rolls are regulated with a hydraulic piston operated by a hydraulic unit outside the machine but controlled from the control panel.

The position of the rolls is calculated with an angular potentiometer, installed behind them (inside the main shaft), that signals the angular position of the roll pins. The electrical panel controlling the entire system can calculate the distance between the rolls and the die through the signal picked up from the potentiometer.

At the electronic panel, the operator chooses the roll position. The panel pressurizes the hydraulic circuit and moves the piston until the rolls reach the desired position.

When the piston has positioned the roll at the distance from the die set by the operator, the circuit is automatically locked by two valves, keeping the rolls in this position.The circuit can achieve a maximum pressure of 250 bar. The pressure required to move the piston, and thus regulate the rolls, is approximately 150 bar.

Position can be regulated quite rapidly: the roll can be brought 7-8 mm closer to or moved 7-8 mm away from the die in approximately 15 seconds.

Reasons for choosing the WAP system

- Precise and quick position of the rolls

- The operator can choose between multiple rolls adjustment positions.

- Through the control panel, the operator can adjust the position of the rolls even if the machine is moving

- Easy maintenance

- Quick to restart the press after a blockage

- More power in recording the roll then with the mechanical adjustment