Consideration on choosing a pellet press

When choosing your first pellet mill or if you want to buy a new one, there are two important factors to consider: production capacity and the product to be pelleted and its granulation.

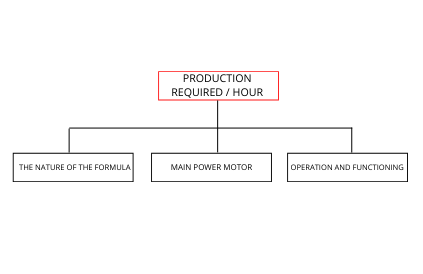

The production capacity defines the quantity of pellets produced per hour, and it is characterized by the following elements:

- The nature of the formula.

- The main motor power

- Operation and functioning

1. The nature of the formula

Each plant has its own specific formulas, which adapt to the needs of use of the locality in which it is located. There are different types, from those for cattle or pigs, to those for chickens or laying hens, passing through small animals, such as rabbits, quail, partridges, trout. Then there are those that deal with mineral compounds, in short, a multitude of formulas.

All these productions do not resemble each other in any way, ranging from the finest granules (broiler) to the largest (mineral compounds). Therefore, dies with holes of diameter and with different compression ratios are used.

Each plant is therefore a case in itself and differs from the others according to the formulation it must produce.The manufacturer, based on the type of formula, studies the type of press and the dies that best suit the purpose.

2. Main motor power

Production is closely linked to engine power, in fact, the greater the power, the greater the range.

This is how we have seen the appearance of real giants on the market. It is interesting to focus on their hourly capacity and the cost of the plant, because the costs do not increase in proportion to the increase in hourly productivity, on the contrary...

A large press is not recommended for plants with many formulas to granulate in small batches.

To use a large machine correctly, large batches (minimum 20 tons) must be processed with few formulas and similar compression ratios.

Unless it is justified and well thought out, we must not make the decision to buy a large press lightly.

The flow rate can vary with the same power and on the same formula, depending on whether you are working dry, with water or with steam.

We must therefore choose and opt for a solution. The formula can strongly influence the choice of a company specialized in the production of mineral compounds, which, and it is an extreme case, will work dry or with little water.

Most of the time, especially today, the vast majority of machines run on steam. If there are no particular reasons, it would be heresy to work with water.

A safety margin must be considered. Finally, available space can be a limiting factor.

3. Operation and functioning

Everyone knows that a press never produces at full capacity, but the values are around 70-80%. The human factor must be taken into consideration, the worker is afraid that his press will flood. To avoid tedious restarting operations, he tends to modify his machine by limiting its capacity. So you will be safe knowing that your pellet press will be able to overcome overloads without risk.

Other times, the machine will not reach its maximum intensity because the steam levels will not be sufficient, resulting in poor productivity (see regulation and control). This and many other cases can affect the entire production. When buying a press, we must also think about staff training.