LERNE MEHR ÜBER UNS

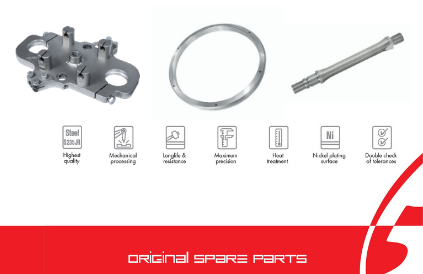

Herstellung von Maschinen, Anlagen und Ersatzteilen für die Futtermittel-, Biomasse-, Recycling- und Düngeindustrie vollständig Made in Italy.

Fortschrittliche Maschinen und zielgerichtete Lösungen für Sieb-, Krümel-, Mahl-, Misch-, Kühl- und Pelletierprozesse.

Messen & Veranstaltungen

HIGHLIGHT

Wir machen die Welt nachhaltiger, indem wir die Produktionsprozesse durch fortschrittlicher Technologie verbessern, mit neuen Produkten , indem wir den Energieverbrauch reduzieren, Abfall und die Verwendung umweltschädlicher Produkte vermeiden und unser Unternehmen in ökologisch nachhaltigen Aktivitäten einbeziehen.

Entdecken Sie unser soziales Engagement und unseren Beitrag zur Erhaltung und Verbreitung der Kunst und Kultur der Region.

People are our main resource and we take care of their health and safety. Mechanics has always been careful to grasp the real need of workers and to translate them into concrete actions to protect employees

"NUMMER" VON LAMECCANICA

MASCHINEN

GELIEFERTE

GELIEFERTE MATRIZEN

PER JAHR

MATRIZEN BOHRUNGEN

IN KM

GELIEFERTE KOLLERHUELSEN

PER JAHR

KANNONEBOHRER

IN TON

Mixing process

Why are mixers so important?

The mixer plays a vital role in the feed production process, with efficient mixing being the key to good feed production. In fact, only the perfect mixing of the feed ingredients will ensure uniform distribution of nutrients, vitamins and minerals, which will result in a homogeneous nutrient content in each feed pellet. Further, it will ensure optimum growth of the animals.

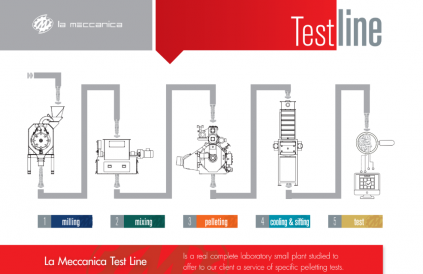

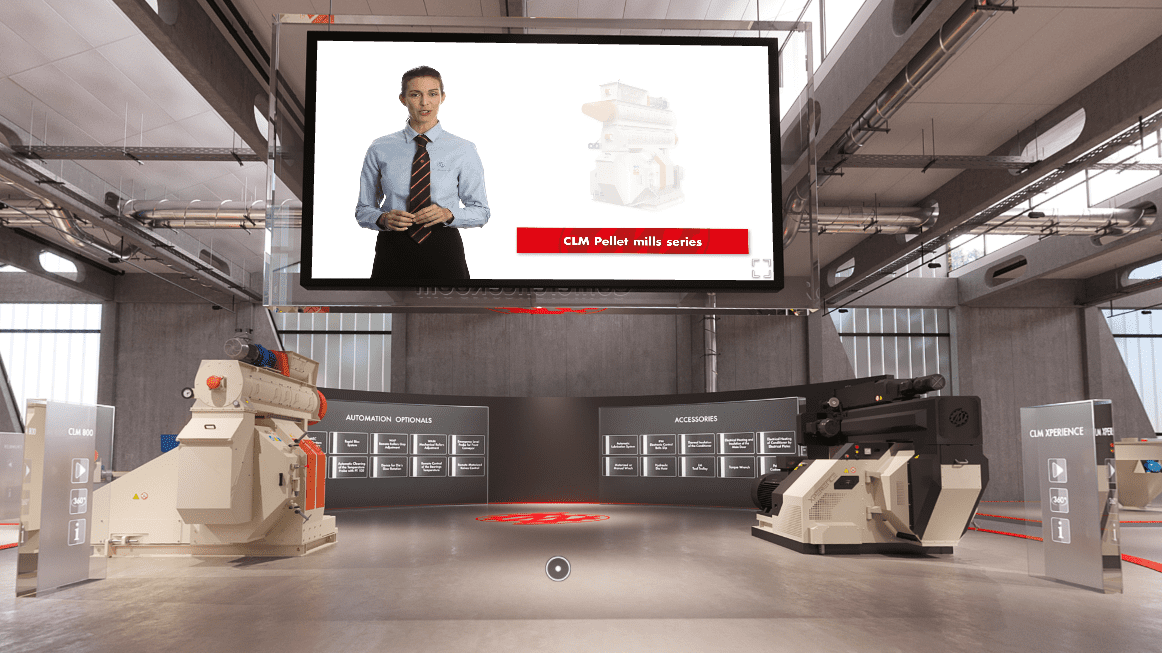

Do you want to know better La meccanica, the products and its history? Visit our company, the conference room, the showroom and the pellet test line! Ask for a guided tour in our virtual platform

or start a virtual visit on your own

_0.png)