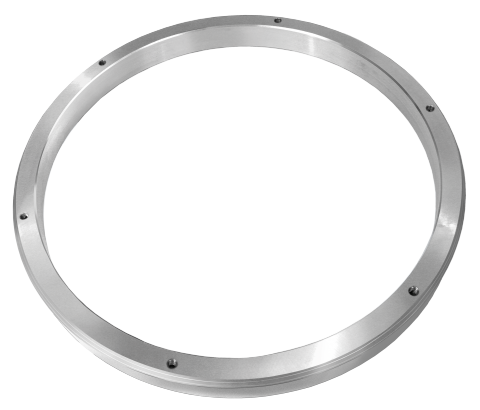

The stress due to the pelleting process creates specific pressures on the housing seat of the die which tends to deteriorate over time.

In particular, a gap between the seat in the rotor and the die can be the result of too much stress. In this case, the die is no longer rigidly fixed, with the consequence of damaging the work surface and breaking the fixing screws.

The wear ring is the solution we have adopted to solve this problem: the ring can be easily replaced to ensure always the correct “anchoring” of the die to the rotor.

Client area

Wear Ring

The ring is made of hardened steel with very tight finishing tolerances.

The ring is made of hardened steel with very tight finishing tolerances.

A quality control guarantees both tolerance (+/- 0.05 mm) and hardness (52-54 HRc).

A quality control guarantees both tolerance (+/- 0.05 mm) and hardness (52-54 HRc).